CVP Systems, Inc.

CVP Systems, Inc. formed in 1972 when Coronet Container Corporation, based in Lombard, Ill., was required to change its technology based on industry requirements to extend shelf life for perishable products. These requirements stated that materials must be enclosed inside a vacuum-sealed package before being placed inside a corrugated box, rather than directly inside. A separate division, Coronet Vacuum Packaging, was developed and split from Coronet Containers in 1975 to become CVP Systems, Inc., based in Downers Grove, Ill., a Chicago suburb. The company employs 40 employees globally; a regional sales force covers the United States, and agents are also located in Europe and Latin America. Industries served by CVP are red meat, poultry, fish, produce and fruit, cheese, nuts, snack foods, and spices. Its modified atmosphere packaging technology also is used in industries other than food, such as for cube reduction and anti-oxidation systems, metal parts packaging, and document storage.

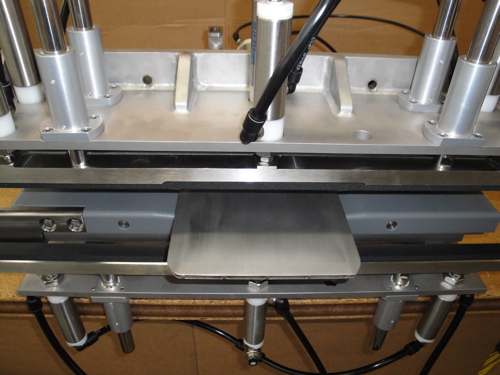

MasterPACKer Eco+

Modified Atmosphere Packaging

Worldwide, Tesco, a global grocery and general merchandise retailer headquartered in Cheshunt, U.K., initiated the demand for modified atmosphere packaging technology in the early 70s. It became one of the first grocers to move away from employing an onsite butcher to using a central processing/distribution system. CVP Systems, in attempt to meet the demand by large poultry and meat packaging companies looking to extend their products’ shelf life, offered its modified atmosphere packaging solutions. This high-efficiency system for packaging of poultry and meats removes air from a package and introduces a new more beneficial atmosphere, depending on the specific product application requirements. Specific mixtures for low-ox applications can be comprised of a mixture of 69.6% nitrogen (N2), 30% carbon dioxide (CO2), and .4% carbon monoxide (CO) or 70% nitrogen and 30% carbon dioxide; it’s based on the premise that bacteria have a difficult time surviving in a low-ox environment because they need oxygen to survive and multiply,” said van Wandelen.Some applications need only high-ox (70% oxygen, 30% carbon dioxide); however, high O2 applications do not attain quite the same shelf life extension as low O2. To improve its technology in modified atmosphere packaging, CVP engineers, through extensive research and development, created its MasterPACKer and just last year its “next generation” MasterPACKer Eco+™. The machine is designed for high-speed cycling and features a high-velocity “Quick Draw” snorkel. In the various process cycles, overwrapped trays containing product are robotically loaded onto a servo driven infeed conveyer. Two to eight trays are inserted into a mother bag as the machine indexes and transfers them to the next station, where a Quick Draw snorkel simultaneously draws a vacuum and inserts a pre-set amount of gas and then seals the bag.